BISON Santy

Hello, I am Santy, the funder of bisonclean.com. I have been in cleaning machinery field for more than 5 years now, and the purpose of this article is to share with you the knowledge related to pressure washer from a Chinese supplier's perspective.

Table of Contents

The pressure washer gun is an essential tool for cleaning tough surfaces, delivering high-pressure water spray to remove dirt, grime, and stubborn stains. It is the main component that directs the water spray from a pressure washer and assists with a variety of cleaning tasks, including vehicles, home siding, decks, and industrial spaces.

Over time, pressure washer guns can encounter problems due to frequent use, improper maintenance, or wear and tear. Prompt servicing of your pressure washer gun will not only extend its life but also ensure optimal performance and user safety. This blog discusses common problems with pressure washer gun, such as leaks, clogs, and low pressure. It also provides steps on how to fix a pressure washer gun.

Safety precautions

1.Familiar with the main components:

- Nozzle: Controls the spray width and intensity.

- Handle: The area used to hold and control the gun.

- Trigger: Control the flow of high-pressure water.

- Hose connection: Links the gun to the pressure washer system to supply water.

When you are familiar with the main components, check for obvious signs of wear, looseness, cracks, or leaks.

2.List the necessary safety measures:

- Before making any fixes, unplug electric models or turn off and disconnect the fuel on gas models.

- After turning off the machine, pull the trigger to release any built-up pressure in the hose. This will prevent accidental spraying during the repair process.

3.Wear appropriate safety equipment:

- Goggles: Protect your eyes from high-pressure water spray, debris, and chemicals.

- Gloves: Protect your hands from cuts, or potential injuries.

- Non-slip footwear: Prevent slips and falls.

pressure washer common problems

1. No water flow

Check the water supply: Check whether the water source switch is turned on and the water flow is sufficient.

Inspect the inlet filter: A clogged or dirty filter can block water from reaching the gun.

Examine the hose connection: Make sure all hoses are securely connected, and inspect hoses (open the hose reel as needed) for kinks and leaks that could restrict water flow.

2.Low pressure

Inspect the nozzle: A clogged nozzle will prevent water from flowing out, and a worn nozzle will restrict the flow of pressurized water.

Check the detergent injector: If the injector is clogged or malfunctioning, it may disrupt the water pressure.

Inspect the inlet filter: Keep your inlet suction strainers clean and use the correct size.

Evaluate the pump performance: A faulty or failing pump can result in low pressure. Inspect for damaged seals or other pump inefficiencies.

3. Gun leaks

Inspect O-rings: Worn or damaged O-rings are common causes of leaks.

Check seals and connections: A seal that is chipped or not tight can cause a leak.

Hose fittings: Look for leaks at the junctions between the hose and the gun; replace cracked or worn fittings.

4. Pulsating pressure

Check the hose: Air trapped in the hose can cause pressure pulsations. Check for loose connections or cracks that could allow air in.

Inspect the pump components: Dirty or damaged pump valves can create uneven water flow, resulting in pulsating pressure.

Inspect filters: Clogged filters in the system can create pressure inconsistencies. Clean or replace filters regularly.

5. Gun trigger failure

Check the trigger mechanism: Check for accumulated dirt or debris, which tends to jam the trigger’s range of motion.

Inspect the spring: A broken or worn trigger spring can cause the trigger to stick or fail. Replace the spring with a compatible part.

Inspect for physical damage: Cracks or breaks in the trigger mechanism require the replacement of the entire assembly.

6. Water backflow into the gun

Check the backflow valve: Inspect the return valve or check the valve for damage or malfunction.

Inspect internal passages: Blockages or cracks in the gun chamber may also cause backflow. Need to be disassembled for inspection.

How to fix a pressure washer gun

1. Nozzle clogged

Step 1: Remove the nozzle from the spray gun.

Step 2: Inspect the nozzle for clogs caused by debris or mineral buildup.

Step 3: Use a small needle, wire, or nozzle cleaning tool to unclog the nozzle. Rinse thoroughly with water.

Step 4: If the nozzle is damaged or worn, replace it with a new nozzle of the appropriate size and type.

2. Increase water pressure

Step 1: Inspect the high-pressure hose for kinks, cracks, or damage. Straighten kinks or replace the hose if necessary.

Step 2: Check other connections, including the water source and inlet filter, ensuring clean water flow and no obstructions.

Step 3: Test the pump’s performance. A malfunctioning pump might require servicing, such as replacing seals or rebuilding pump components.

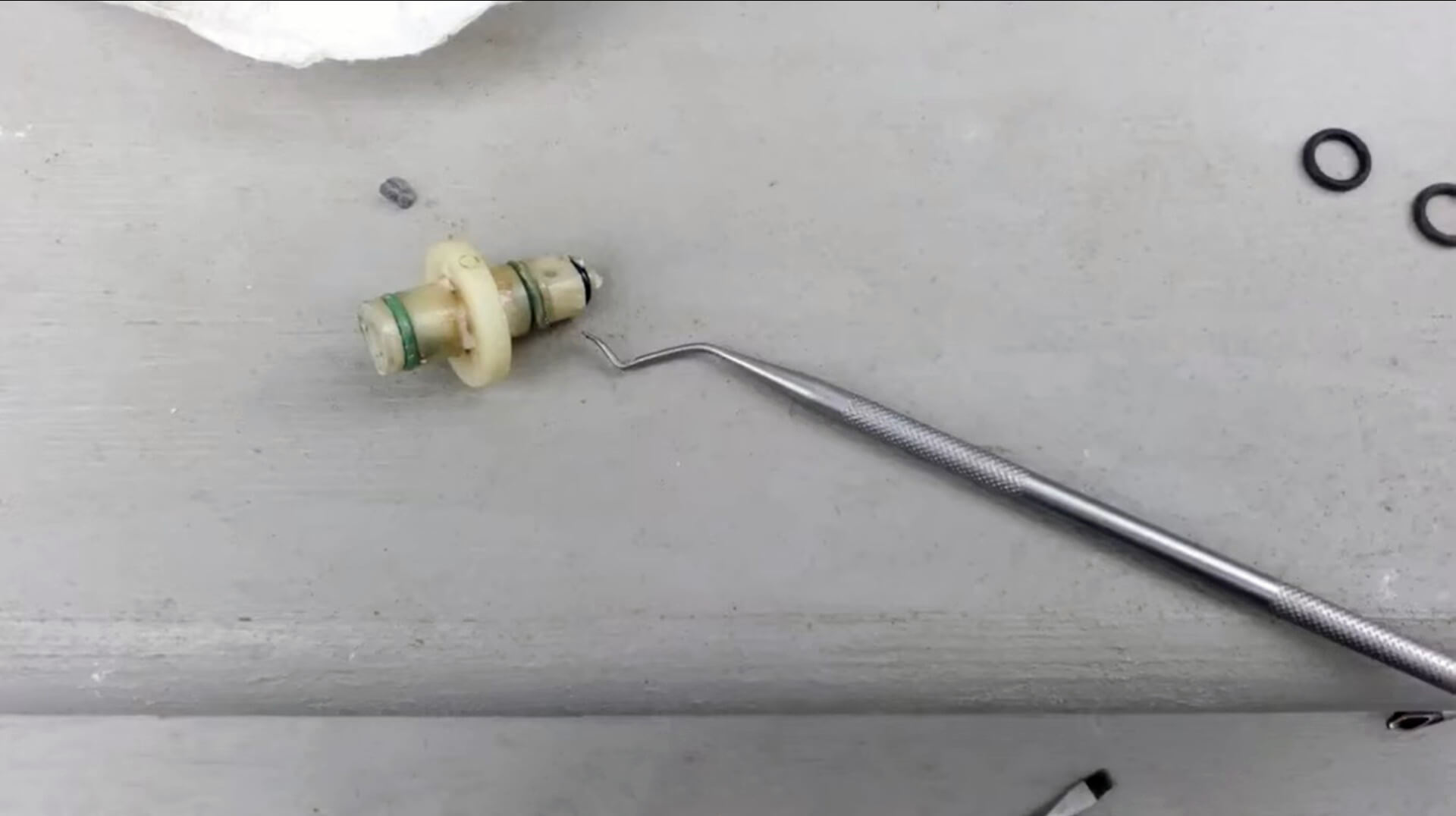

3. Fix O-ring leakage

Step 1: Try tightening the connector to see if it stops the leak. Suppose it doesn’t open the connector with pressure and focus on the o-rings. Then, disassemble the spray gun by following the user manual or carefully removing the screws.

Step 2: Check that all O-rings inside the gun are intact or appear.

Step 3: Replace the damaged O-rings with the correct size replacements (O-rings are typically available in repair kits).

Step 4: Apply a suitable lubricant or grease to the new O-rings to ensure a proper seal and prevent damage during operation.

Step 5: Reassemble the gun and test for leaks.

Step 6: If they appear in good condition, lubricate the O-rings.

4.Fix trigger failure

Step 1: Disassemble the trigger mechanism by carefully unscrewing the components.

Step 2: Inspect the trigger assembly for physical damage, broken parts, or spring misalignment.

Step 3: Clean any dirt, grease, or debris from the trigger.

Step 4: Depending on how worn or damaged the spring or trigger bar is, it may be time to replace it.

Step 5: Reassemble the trigger mechanism, ensuring smooth operation of the trigger.

5. Fix internal component issues

Step 1: If you disassemble the gun and find severe internal damage (cracks in the gun casing or clogged internal passages), evaluate whether the gun needs to be replaced.

Step 2: For repairable blockages, clear the internal passages using compressed air or water and remove any buildup.

Step 3: Replace the pressure washer gun. Disconnect the pressure washer hose from the trigger handle, select the matching pressure washer gun model, remove the spray wand and nozzle assembly from the trigger handle, and apply some lubricant to the O-ring. Then screw the high-pressure hose onto the new pressure washer gun.

Step 4: Start the pressure washer and verify that the new spray gun works properly.

Conclusion

A well-functioning pressure washer gun is key to maximizing your cleaning power, so fix is a worthwhile investment. In this article, we provide a step-by-step guide to fixing your pressure washer gun, including no water flow, repairing O-ring leaks, increasing pressure, Pressure washer gun failure, and addressing other necessary repairs. However, BISON recommends that in more complex cases where internal parts are damaged or severely worn, a new pressure washer gun be purchased to ensure safe water jetting from the pressure washer.

BISON is a professional supplier of pressure washers and pressure washer accessories. With rich product lines, innovative technology and commitment to quality, BISON has accumulated a good reputation among customers. If you are a dealer looking for cost-effective pressure washer products, please explore BISON’s products and improve your cleaning business.

FAQs About Fix A Pressure Washer Gun

The pressure washer provides pressurized water, and the spray gun acts as a tool for the user to direct and control this pressure, and together they form a powerful cleaning system. The water then flows through the unloader and output pipe to the pump and the spray gun’s hose. Pressurized water is released when the spray gun trigger is depressed. Eject through the trigger handle assembly or a separate spray wand and nozzle. When the trigger is released, the high-pressure water flow stops immediately.

- Use the correct water pressure settings.

- Tighten the connector when the pressure washer is off. Water flow sometimes loosens the knob.

- Apply silicone grease to the valve at least once a month. This will keep your knock smooth and will not create any leaks.

- Check and clean filters and lubricate parts regularly.

- After use, clean the pressure washer gun thoroughly and store it in a dry, safe place.

You might also enjoy

Questions?

Contact Us Today.

Find more?

Related Posts

How to use a pressure washer gun

BISON will cover everything from pressure washer gun operation basics to advanced techniques for tackling tough stains and delicate surfaces.